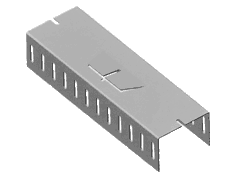

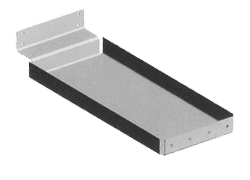

The Curved Angle Deflection System is a patented U.L. tested for 1-2 hour fire and seismic movement of 1 1/2". Slots for deflection are spaced every one inch on center. Provides a flange of 2 1/2" at the head-of-wall for ceiling attachment. The Curved Angle System can be used for retro-fitting of pre-standing curved walls where deflection at the head-of-wall is required by code.

This two piece system can be used with any wall width. Tack slots allow for upward and downward movement of the structure while maintaining a positive attachment/secure installation.

Meets the cycle, fire resistance, and hose stream testing requirements of the BOCA Code (1999) Section 709; Standard Code Section 705; UBC Section 706 and the IBC 2009. Underwriters Laboratories, Inc. Tested and Listed.

ASTM E- 1966 Hose Stream Test Procedure

14.1 Requirements.

14.1.1 Within 10min after the end of the fire endurance test, subject test specimens that are extensions of walls to the impact, erosion, and cooling effects of a host stream.

14.1.2 Conduct the hose stream test on a duplicate test assembly which has been conditioned, movement cycled, and subjected to a fire test equal to one-half of the fire endurance but not more than 60 min.

IBC 2009

Section 702.

Definitions.

A FIRE-RESISTIVE JOINT SYSTEM is an assemblage of specific materials or products that are designed, tested, and fire-resistance rated in accordance with UBC Standard 7-1 to resist, for a prescribed period of time, the passage of fire through joints.

Section 706.2 Fire-Resistive Join Systems.

5. Joint systems shall be tested at the maximum joint width for which they are designed. Joint systems designed to accommodate movement shall be expanded to the maximum joint opening width for which they are intended to function.

7. Joint systems designed to accommodate movement shall be preconditioned by cycling between the minimum and the maximum joint opening width for which they are intended to function for the number of cycles specified in TABLE 7-D.

Curved Angle Deflection Track is the only curved track system to be fully cycled 500 times and fire & hose stream tested in accordance with ANSI/UL 2079 (2001) and the ASTM Standards, E-119 & E-1966.

UBC 1997

Section 706 - Fire Resistive Joint Systems

Section 709 - Walls and Partitions

BOCA 1999

Section 709 - Fire Resistive Joint Systems

Section 711 - Fire Partitions

Standard Code 1997

Section 704 - Fire Resistant Joint Systems

Section 705 - Fire Resistant Joint Systems

IBC 2009

Chapter 7 - Fire Resistant Joint Systems